Advancements in Digital Textile Printing for High-Precision Customization

Advancements in Digital Textile Printing for High-Precision Customization

The textile industry is undergoing a transformative shift, driven by digital textile printing technologies that enable high-precision customization. These advancements fundamentally alter production approaches for manufacturers and designers. Unlike traditional screen printing methods, which require extensive setup time and high minimum order quantities, modern digital textile printing delivers intricate, multi-color designs with exceptional accuracy while maintaining cost efficiency and environmental sustainability. This paradigm shift has reshaped the competitive landscape, empowering companies of all scales to respond rapidly to market trends and consumer demands for personalized apparel and promotional products.

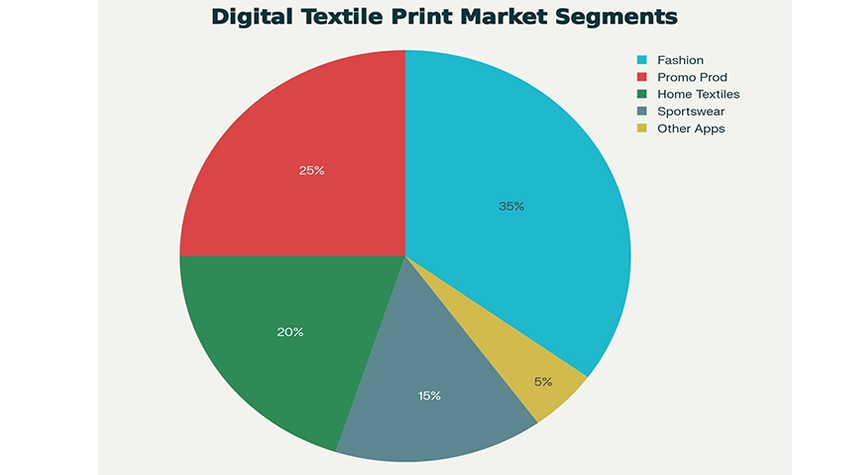

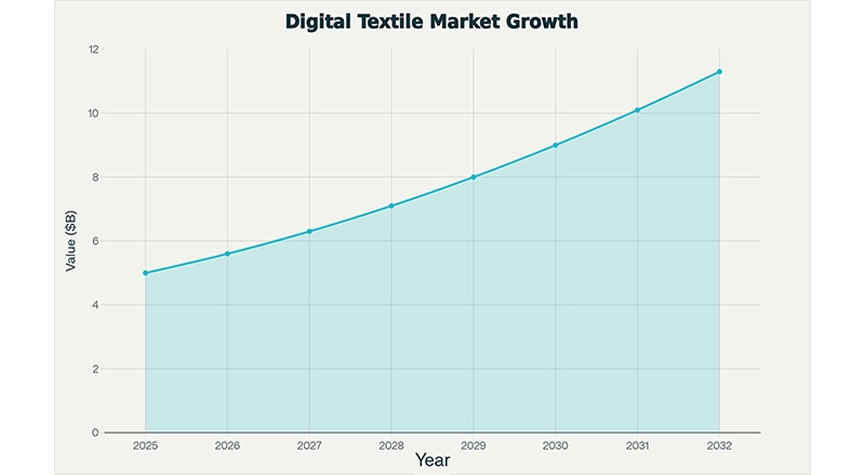

The global digital textile printing market reflects this transformation. According to a November 2025 report by Persistence Market Research, the market reached approximately US$5 billion in 2025 and is projected to grow to US$11.3 billion by 2032, at a compound annual growth rate (CAGR) of 12.5%. This rapid expansion underscores the industry's recognition that digital textile printing represents not merely an incremental improvement but a fundamental reengineering of production capabilities. Manufacturers adopting these technologies gain competitive advantages, including accelerated time-to-market, enhanced design flexibility, and significant reductions in operational costs.

Understanding the Core Technologies

Key Technologies Driving the Revolution

The foundation of modern digital textile printing lies in advanced inkjet technology, combined with sophisticated ink formulations and precise printhead engineering. Digital printers utilize specialized water-based pigment inks that penetrate fabric fibers with exceptional accuracy, producing designs resistant to fading after multiple washes while preserving vibrant color saturation. This process converts digital design files into precise droplet patterns, depositing microscopic ink droplets with superior placement accuracy to achieve photorealistic reproduction and fine detail.

Direct-to-Garment (DTG) printing is a primary category, employing inkjet technology to apply water-based inks directly onto fully assembled garments. This approach is particularly suited for low-volume customization and personalized apparel, enabling on-demand printing of individual designs without screen preparation or setup time. DTG systems can achieve print resolutions up to 1440 × 1440 dpi, facilitating the reproduction of subtle details and smooth color gradients that traditional methods cannot replicate.

Direct-to-Film (DTF) printing represents another major segment, where designs are first printed onto specialized polyester film and then transferred to fabric using heat press equipment. DTF has gained widespread adoption, with estimates indicating substantial production volumes in recent years and a significant share of global t-shirt decoration. The DTF process accommodates a broader range of fabric compositions, including challenging materials such as fleece, nylon, and polyester blends, delivering exceptional color durability and vibrancy.

Comparison of DTG and DTF Technologies

Achieving Superior Color Reproduction and Visual Excellence

High-precision color accuracy in digital textile printing, particularly for customization, relies on advanced color management systems and complex ink formulations. Modern digital textile printers employ extended gamut technology—incorporating complementary orange, green, and violet ink channels alongside traditional cyan, magenta, yellow, and black (CMYK)—to reproduce approximately 90% of Pantone spot colors with high fidelity (based on reports from FESPA and Pantone).

This represents a significant advancement over conventional CMYK systems, which typically cover only about 60% of brand spot colors, enabling more precise matching to brand specifications and designer intent.

Water-based pigment inks used in contemporary digital systems offer substantial environmental improvements compared to traditional screen printing while exceeding customer expectations for color vibrancy and wash fastness. These advanced formulations achieve color saturation through molecular bonding with fabric fibers rather than surface coating, resulting in prints with soft hand feel that retain aesthetic appeal across multiple wash cycles.

Color management in high-precision digital printing requires calibrated measurement devices (such as spectrophotometers) and substrate-specific ICC profiles. These tools and protocols ensure color consistency across different fabrics and production batches. Modern digital systems also incorporate intelligent temperature control and automated printhead protection mechanisms, maintaining color accuracy during extended runs and eliminating common issues in legacy methods, such as color drift and inconsistency. In essence, without precise ICC profiling and regular spectrophotometer calibration, color variance would occur across production; however, advanced systems ensure uniformity even after hours of continuous operation.

Precision, Speed, and Scalability

On-Demand Production and Rapid Adaptability

Accelerated production timelines represent one of the most significant competitive advantages of digital textile printing. High-speed single-pass printers now achieve outputs up to 1080 square meters per hour while preserving photorealistic quality and high color accuracy.

These systems eliminate minimum order quantity constraints, making print-on-demand business models economically viable—from single-unit orders to large-scale production.

Traditional production methods often require substantial investment in initial inventory. Studies indicate that 30–40% of conventionally produced apparel remains unsold, leading to waste or financial loss. Digital textile printing, by contrast, enables production precisely aligned with actual demand. This approach allows businesses to preserve cash flow, allocate capital more efficiently, and respond swiftly to emerging market trends without excess dead stock. The technology's high scalability addresses diverse needs, from custom promotional items with personalized logos to full seasonal fashion collections. Designers can rapidly prototype and iterate based on customer feedback without incurring prohibitive costs or delays.

This flexibility is particularly valuable in fast fashion, where design cycles have compressed from monthly to weekly or even daily updates.

In simple terms, digital printing eliminates the need to stockpile forecasted apparel that may never sell. Only what the customer truly desires is produced—quickly, accurately, and without additional financial risk.

Advanced Design Capabilities

Unlimited Creative Expression

Digital textile printing for high-precision customization removes the design limitations inherent in traditional screen printing. Conventional methods typically support up to nine colors, with additional colors dramatically increasing costs, whereas digital systems can reproduce up to 16 million color variations without extra setup expenses.

Designers can now seamlessly incorporate photorealistic gradients, complex patterns, fine artistic details, and multi-layered advanced graphics—elements that were technically infeasible or economically unjustifiable in traditional processes.

This capability for handling complex design elements has unlocked unprecedented opportunities for personalization and customization. Fashion brands leverage the technology for exclusive collections and limited-edition designs that convey individuality and uniqueness to customers.

Mass customization—the economical production of personalized items at scale, once a theoretical concept—has become operational reality through digital textile printing advancements.

Use of high-resolution (300 DPI) image files ensures exceptional print quality even on large fabric surfaces, while 150 DPI suffices for designs viewed from a distance. These technical specifications guarantee faithful reproduction of photographic-quality prints and intricate artwork, enabling applications such as fine art reproductions, museum-grade prints, and cutting-edge fashion requiring technical precision.

In summary, digital printing functions like a professional photographic printer on fabric—any computer-generated design comes to life with full detail and natural colors, without color limitations or added costs for low volumes.

Environmental Responsibility and Sustainability

Ecological Advantages of Modern Textile Printing

The environmental impact of textile production is a critical concern for manufacturers and environmentally conscious consumers. Digital textile printing offers measurable ecological benefits over traditional methods.

Digital systems reduce water consumption by up to 95% compared to conventional rotary screen printing (per FESPA and Advanced Market Analytics reports). This savings primarily results from eliminating extensive washing and rinsing processes in legacy methods. Precision droplet deposition in inkjet technology further minimizes ink waste, with virtually every droplet contributing to the final design rather than being absorbed unnecessarily or washed away.

Energy consumption in digital textile printing is approximately 30% lower than conventional approaches, due to the elimination of energy-intensive steps such as screen preparation, separate curing, and fixation. Advanced single-stage solutions integrating pretreatment, printing, and fixation in one production line reduce operational costs by up to 50% while lowering energy and chemical use by up to 80%.

Water-based pigment inks in modern systems eliminate hazardous chemical emissions and minimize wastewater compared to reactive printing methods. These technological shifts align with the sustainable fashion movement, where surveys indicate that 94.6% of consumers are willing to pay more for environmentally responsible products.

Manufacturers adopting high-precision digital textile printing for customization simultaneously achieve improved environmental performance, reduced operational costs, and responsiveness to growing demand for responsibly produced apparel.

Digital printing not only consumes less water and energy while generating less waste but also enables brands to lower costs and build a sustainable, green market image—a key success factor in today's fashion industry.

Applications Across Multiple Industries

Fashion, Promotional Products, and Beyond

The versatility of digital textile printing has driven widespread adoption across diverse applications beyond traditional fashion. In fashion, it enables custom prints on various fabric substrates, from luxury silk and premium cotton to modern synthetics, producing unique aesthetic outcomes and allowing designers to create signature collections that differentiate brands visually.

The promotional products sector is among the most dynamic applications, with DTG and DTF adding significant value by enabling corporate branding on custom apparel, branded bags, scarves, flags, and banners with vibrant, durable, high-quality prints that leave lasting impressions. Critically, economical small-run production facilitates truly personalized promotional items—incorporating individual names, departmental logos, or event-specific designs.

Home textiles have seen substantial growth, as consumers demand personalization; digital printing enables custom curtains, upholstery, bedding, and decorative fabrics with preferred designs.

In sportswear and performance apparel, high durability and precision allow functional garments with intricate graphics, integrated moisture management, and custom fit.

Applications continue to expand, with innovative uses for digitally printed textiles emerging regularly.

In practical terms, digital textile printing is no longer limited to t-shirts—from luxury apparel and promotional items to home décor and sportswear, virtually any fabric can receive custom designs at high quality and desired volumes. This flexibility has opened creative boundaries for designers and brands.

Technical Requirements and Best Practices

Achieving Optimal Results in Digital Printing

Successful implementation of high-precision digital textile printing for customization demands adherence to precise technical protocols to ensure consistent, superior quality.

Design File Resolution Standards:

- Effective resolution should exceed 100 pixels per inch (PPI).

- 150 DPI is fully acceptable for standard applications.

- 300 DPI is recommended for maximum-precision work (e.g., very fine details and smooth gradients).

Note: Resolution is the final value after sizing and layout in software (e.g., Photoshop or printer RIP). Accurate calculation during source file scaling is essential to prevent quality degradation.

Color management protocols require calibrated measurement equipment (e.g., spectrophotometers) and dedicated ICC profiles for each fabric type. These ensure precise color verification, printhead calibration, and consistency throughout production, matching designer specifications exactly.

Modern digital systems feature automated calibration routines, maintaining color accuracy without manual intervention and significantly reducing operational complexity.

Fabric Preparation:

Proper fabric preparation is critical for final print quality, especially in DTG on dark garments or synthetic fabrics. Pretreatment enhances ink absorption and adhesion, improving wash fastness and color vibrancy.

Post-print fixation (curing) via heat or steam is essential, enabling water-based inks to properly bond within fabric fibers, forming durable connections resistant to repeated, prolonged washing without fading or damage.

Practical workshop tip: Incorrect pretreatment or heat fixation yields poor results even with the best printer. Adhering to these protocols ensures professional, durable, precise prints—whether for single-unit orders or mass production.

Market Growth and Future Trajectory

Expanding Outlook for Digital Textile Printing

The rapid growth of the digital textile printing industry reflects fundamental shifts in consumer preferences, production methods, and competitive dynamics.

DTG and DTF technologies are particularly well-suited for fast fashion and e-commerce environments requiring rapid product updates, extensive design variety, and short delivery times. These industries' demands for frequent design iteration and quick launches align perfectly with digital printing's strengths in flexibility and production acceleration.

Ongoing innovations in automation, advanced printhead designs, and specialized ink chemistry continually enhance operational and economic viability. Companies such as Kornit Digital, Epson, Mimaki, and others have introduced systems that increasingly minimize auxiliary pre- and post-processing equipment while reducing reliance on specialized operators.

This democratization of technology enables smaller companies and individual entrepreneurs to compete effectively in customization markets previously dominated by large producers.

Regionally, extensive investments in China have played a pivotal role in explosive DTF adoption, demonstrating its compatibility with ultra-fast fashion retail needs. As technology matures and costs decline, adoption is expanding geographically and across industries, with substantial growth anticipated from 2025 to 2032.

ntegration with Emerging Technologies

Smart Fabrics and Future Possibilities

Convergence of digital textile printing with complementary technologies opens innovative horizons. Integration of 3D printing capabilities with conventional digital textile methods enables complex fabric structures with genuine texture, depth, and dimensional effects—previously impractical.

Wearable electronics represent another compelling frontier, incorporating conductive threads, embedded sensors, and interactive display elements. Digital textile printing seamlessly combines these functional components with aesthetic designs, producing garments that are both attractive and intelligent.

Smart textiles with embedded technologies require precise positioning and flawless integration of conductive and functional elements with decorative prints. The inherent precision and flexibility of digital textile printing position it uniquely to support these innovations, enabling simultaneous application of aesthetic prints and functional circuitry in integrated workflows.

The evolution of high-precision digital textile printing for customization constitutes a true paradigm shift in the textile industry. It delivers unprecedented combinations of design flexibility, production efficiency, and environmental responsibility.

As consumer demand accelerates for personalized products and fashion cycles compress, manufacturers mastering this technology will secure substantial competitive advantages in rapid responsiveness, boundless creativity, and operational sustainability.

Looking ahead, continuous innovations in printing equipment, ink formulations, and complementary technologies promise further possibilities, solidifying digital textile printing as the vanguard of textile industry evolution in the coming years.

♦ References

►https://www.globaltextiletimes.com

.

.

Please Follow us on Social Media.

|  |  |  |  |